Ammonia refrigeration is growing popular in the cooling industry. Industries have started to explore sustainable solutions due to strict global environmental policies and refrigerant regulations. Among them, ammonia has emerged as a powerful alternative to synthetic refrigerants based on chlorine and fluorine. Its eco-friendly nature, cost-effectiveness, and efficiency make it an ideal option for industrial and commercial refrigeration. It is one of the best solutions for large-scale applications such as district cooling.

Traditional refrigerants, such as chlorofluorocarbons (CFCs) and hydrofluorocarbons (HFCs), have high ozone depletion potential (ODP) and global warming potential (GWP). In contrast, ammonia presents itself as a feasible and responsible replacement. It has zero ODP and an extremely low GWP. Thus, the ammonia refrigeration plan is compliant with environmental regulations. But ammonia’s use in refrigeration started in the 19th century. It was widely used before synthetic refrigerants came up in the 20th century.

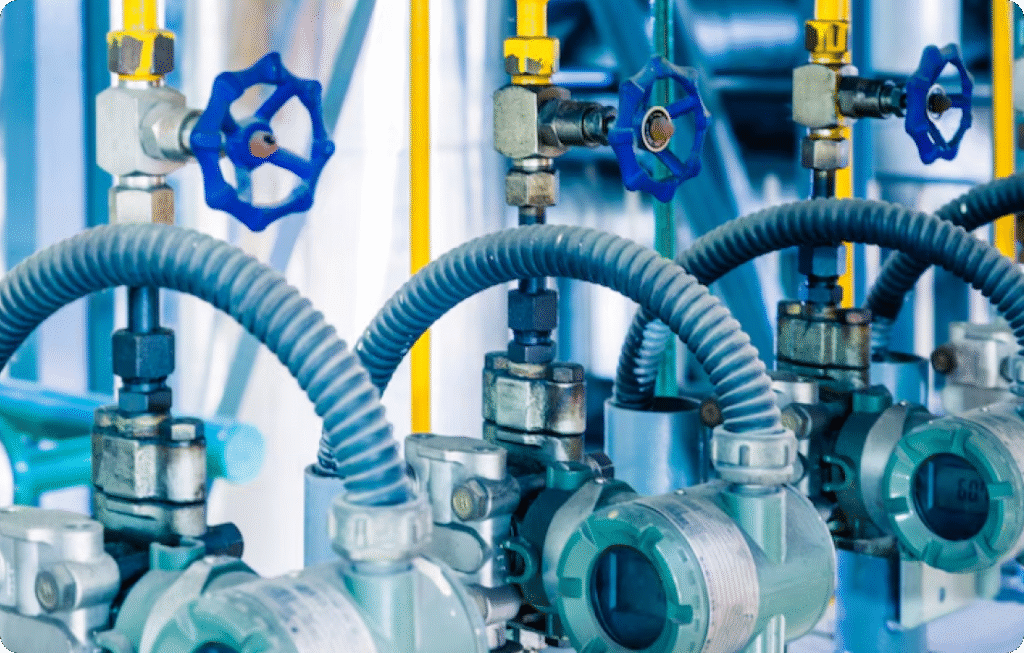

At its core, ammonia refrigeration is a type of system that uses ammonia as the refrigerant. Ammonia is a compound made up of nitrogen and hydrogen. In refrigeration systems, it undergoes a thermodynamic cycle similar to other refrigerants. The process begins with the compression of ammonia gas. It increases its pressure as well as temperature. Once compressed, the gas passes through a condenser where heat is removed, and the ammonia condenses into a liquid.

After that, this high-pressure liquid is passed through an expansion valve, where its pressure drops significantly. As it evaporates at this lower pressure, it absorbs heat from its surroundings. Thus, it creates a cooling effect. Industrial workers repeat this cycle continuously to maintain the desired temperature in a given space or system.

Ammonia refrigeration systems are in rising demand with their exceptional thermodynamic properties. Ammonia absorbs a large amount of heat during the evaporation process. It enables highly effective and efficient cooling. At full capacity, ammonia systems can be up to 20% more efficient than other industrial refrigeration systems. Most importantly, this efficiency doesn’t drop remarkably at part-load conditions. So, it is beneficial for operations with fluctuating cooling demands, but it needs ammonia awareness in NSW for safety.

Furthermore, ammonia refrigeration systems are suitable for various industrial cooling requirements, from ultra-low temperatures for freezing applications to moderate cooling for storage and processing environments. In addition, ammonia is less expensive than many synthetic refrigerants. Sometimes, it costs as little as one-tenth of the price. Besides, ammonia systems are known for their low operational expenses, because of their energy efficiency and the durability of the equipment used.

The type of ammonia used in refrigeration must follow rigorous purity standards, and the industries maintain ammonia refrigerant awareness. It is chemically known as NH₃ and catalogued under the United Nations Chemical I.D. #1005. Moreover, ammonia is produced naturally as well as synthetically. Ultimately, it is used widely in agriculture and industry. People utilise it as a fertiliser or an antifungal.

But, it is only around 2% of the approximately 100 million metric tons produced globally. For this specific application: The ammonia must be at least 99.98% pure, with minimal amounts of water, oil, and other non-condensable gases. The highly pure nature of ammonia ensures optimal performance and prevents damage to system components.

In terms of applications, ammonia refrigeration dominates large-scale facilities, such as food and beverage manufacturing plants, cold storage warehouses, chemical processing facilities, breweries, and petrochemical operations. Its use is prominent in environments where cooling requirements are continuous and significant in volume. But every industry requires ammonia awareness in NSW. In food processing plants, ammonia refrigeration helps maintain the cold chain.

Since it supports freezing, chilling, and storage operations for perishable products such as meat, dairy, seafood, fruits, and vegetables, it is an appropriate solution for these industries. Cold storage warehouses and refrigeration plant operators rely on ammonia systems not just for food. Rather, they use ammonia for pharmaceuticals, chemicals, and other temperature-sensitive products.

In the beverage industry, especially breweries, ammonia plays a key role in controlling temperatures during brewing, fermentation, and storage stages. The chemical and petrochemical sectors also benefit greatly from ammonia refrigeration systems. Here, ammonia is used to cool reactors, equipment, and storage tanks, as well as in natural gas processing. But each of the industries should have the necessary spatial infrastructure and ammonia safety training to accommodate ammonia systems.

Despite its numerous advantages, ammonia does come with certain challenges, such as safety. Ammonia is toxic and has a pungent smell that can be irritating even in small concentrations. Exposure to high levels can be dangerous. So, it is essential to design systems that minimise the risk of ammonia leak. It will ensure proper containment and ventilation. That is why ammonia refrigeration has traditionally been confined to larger facilities. There, its use can be managed with ammonia safety training. However, modern technology and improved safety protocols make ammonia refrigeration suitable for an extensive range of applications.

As industries continue to search for alternatives to conventional refrigerants, ammonia has an important role in the next generation of cooling systems. If you want to shift to ammonia refrigeration or are looking to implement a new cooling system altogether, now is the time to explore its benefits. At Easy Chill Services, we are ready to make you understand the options with ammonia awareness in NSW. Also, our team will guide you through the process of creating a safe, efficient, and cost-effective solution.

We help companies transition to this refrigerant, more than just to comply with current regulations. Instead, you will get solutions to future-proof your industrial operations. The best part is: We celebrate ammonia safety days in regions like New South Wales (NSW), Victoria (VIC), Queensland (QLD), South Australia (SA), Western Australia (WA), Tasmania (TAS), Australian Capital Territory (ACT), Northern Territory (NT). Contact us to learn in detail.

At Easy Chill Services, we deliver high-performance industrial refrigeration…

At Easy Chill Services, we believe that knowledge is the first line of defence when working with hazardous…

In facilities using ammonia refrigeration systems, preparedness is critical. At Easy Chill Services…

Ensuring the safe operation of ammonia refrigeration systems requires more than just proper equipment—it demands regular, expert evaluation…

Schedule your expert service or consultation with our refrigeration specialists today.

Our expert team is committed to delivering reliable and efficient solutions that ensure optimal system performance in every industrial plant.

Feel free to reach out to us anytime for any concerns regarding ammonia training or the industrial refrigeration system. Good luck!