Ammonia (NH₃) is a versatile chemical compound. It is widely used in various industries, including refrigeration, fertiliser manufacturing, and chemical processing. The efficiency, low cost, and unique chemical properties of ammonia determine its significance in various applications. Despite its usefulness, ammonia can be hazardous if mishandled. A major concern across ammonia-handling industries is the risk of ammonia leaks. It can lead to severe health issues, property damage, and environmental harm.

At standard temperature and pressure (STP), the density of ammonia is about 0.73 kg/m³. It is lighter than air, which has a density of around 1.2 kg/m³. So, ammonia will rise and disperse into the air, but under certain circumstances. In confined or low-ventilation spaces, ammonia can accumulate and pose an immediate danger to anyone nearby. Therefore, ammonia safety training is necessary for the industries that utilise ammonia in their production procedures.

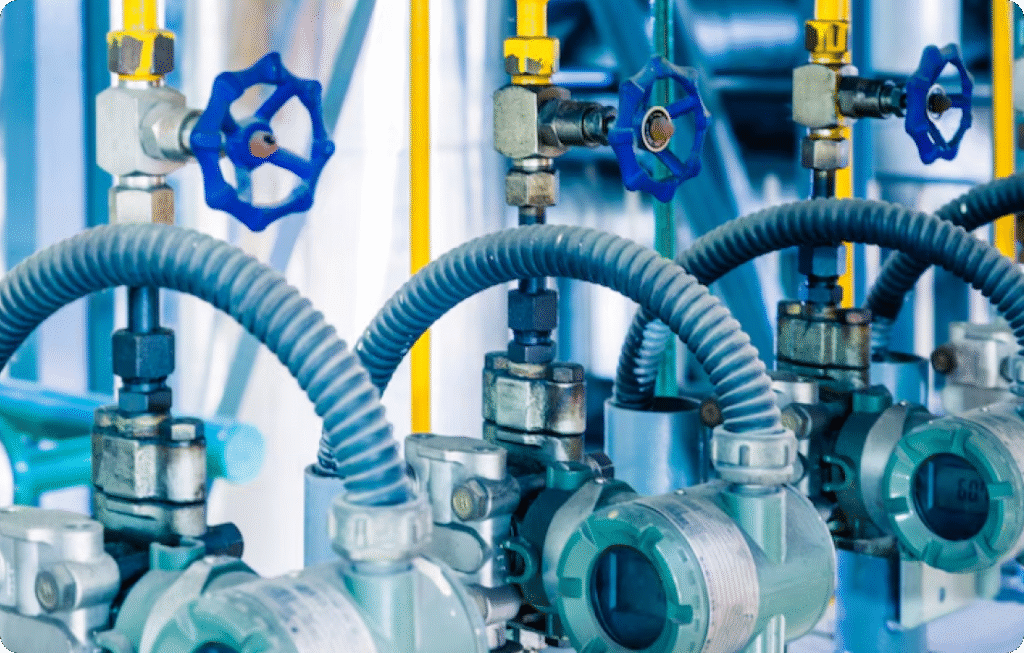

Ammonia leaks can result from multiple causes, and they remain a serious hazard in industries that rely heavily on ammonia-based systems. Equipment failure, where pipe bursts or pressure loss in refrigeration units can cause unintended releases. Furthermore, ammonia is typically stored in pressurised tanks or piping systems that must be routinely inspected and maintained.

If these systems deteriorate or are improperly sealed, the likelihood of a leak will increase. Sometimes, ammonia stored at low temperatures can become unstable when exposed to higher temperatures. It leads to the rise of pressure and a possible rupture of the containment system. For a good reason: Industrial owners should conduct an ammonia refrigeration audit.

Due to the toxic, corrosive, and volatile nature of ammonia, a small leak can result in widespread health risks and environmental contamination. So, it is crucial to understand the severity of ammonia leaks and the impact they can have on human health.

Once released, ammonia rapidly becomes a respiratory threat. Inhalation of low levels can irritate the throat and lungs. This, in turn, results in coughing, wheezing, and shortness of breath. In the severe cases, prolonged exposure can cause bronchitis or chemical pneumonitis. If the concentration is high enough, respiratory failure may occur, which is a life-threatening emergency.

The corrosive nature of ammonia can cause chemical burns on the skin and eyes. Its exposure to vapour or liquid ammonia can result in painful injuries. For the skin, even diluted forms of ammonia can cause dermatitis, irritation, or long-term damage if not washed off immediately.

Ammonia can cause anything from minor irritation to corneal burns or even permanent blindness. For this reason: Individuals working in environments where ammonia is used must wear appropriate protective gear at all times and need ammonia breakdown support.

Another critical hazard associated with ammonia is its explosive potential. When mixed with air at concentrations between approximately 15% and 28% by volume, ammonia becomes highly flammable. It will make leaks dangerous in enclosed spaces where gas can accumulate and possibly ignite due to a spark or open flame.

Workers exposed to low levels of ammonia over time may develop respiratory conditions like asthma or emphysema. Prolonged skin contact can result in persistent skin disorders. At the same time, repeated exposure may also dull the sense of smell. It makes it more difficult to detect future leaks. Following this, ammonia safety audits in NSW are an obligatory solution for industries, depend on ammonia.

Organisations must follow the safety regulations of the Occupational Safety and Health Administration (OSHA) and the U.S. Environmental Protection Agency (EPA). These agencies establish permissible exposure limits and mandate safety training. Also, they provide guidelines for emergency preparedness and equipment handling with ammonia safety audits in NSW. Compliance with these standards is not just a legal requirement. Rather, it is a moral obligation to protect human life and the environment. Read on to discover the precautions:

The installation of NH₃ gas detectors will create defences against ammonia leaks. These devices monitor air quality and trigger alarms if ammonia concentrations exceed safe limits. A properly installed and well-maintained detection system allows for rapid response. Above all, it minimises health hazards and controls the spread of the leak. Detectors should be strategically placed around high-risk areas, especially near equipment and storage facilities where leaks are less frequent.

Ventilation also plays a crucial role in managing ammonia safety. Despite being lighter than air, ammonia gas can collect at ground level in poorly ventilated areas and cause a serious hazard. Ventilation systems, including exhaust fans and vent pipes, should be incorporated into facility designs. It makes sure that gas does not accumulate and allows for its safe dispersal. Plus, air filtration systems can help maintain air quality, especially in enclosed or semi-enclosed workspaces.

Industries must develop comprehensive ammonia emergency response plans to mitigate risk factors due to ammonia leakage. These plans should outline evacuation routes, emergency contact procedures, and first-aid protocols in the event of an ammonia leak. All employees must have ammonia safety days. In many cases, fast and efficient evacuation, combined with access to medical assistance, can mean the difference between a minor incident and a major tragedy.

Equipping workers with the proper personal protective equipment (PPE) is another critical safeguard. Respirators help filter out ammonia vapours and protect against inhalation injuries. Chemical-resistant gloves and suits reduce the risk of skin contact. On the other hand, safety goggles or full-face shields protect the eyes from ammonia vapours or splashes. Regular inspection and replacement of PPE are essential to maintain its effectiveness. Employers should ensure that staff are well-informed about the proper use and limitations of all equipment.

Perhaps, routine maintenance of ammonia systems is the most proactive step an organisation can take. Valves, seals, joints, and pipelines should be inspected frequently for signs of corrosion or wear. Any worn or damaged components should be replaced immediately. Preventive maintenance not only ensures system efficiency but also drastically reduces the risk of unexpected leaks in regions like New South Wales (NSW), Victoria (VIC), Queensland (QLD), South Australia (SA), Western Australia (WA), Tasmania (TAS), Australian Capital Territory (ACT), Northern Territory (NT).

Nonetheless, ammonia is an essential industrial resource. It demands a high level of respect and responsibility in its handling. Understanding the sources of ammonia leaks, recognising the symptoms of exposure, and implementing ammonia safety audits in NSW are critical to ensuring a safe workplace. With proper detection systems, protective equipment, routine maintenance, and adherence to safety protocols, industries can reduce the threat of ammonia leaks. They continue to benefit from its applications without compromising human health or environmental integrity. Get in touch with Easy Chill Services to get safety solutions at hand.

At Easy Chill Services, we deliver high-performance industrial refrigeration…

At Easy Chill Services, we believe that knowledge is the first line of defence when working with hazardous…

In facilities using ammonia refrigeration systems, preparedness is critical. At Easy Chill Services…

Ensuring the safe operation of ammonia refrigeration systems requires more than just proper equipment—it demands regular, expert evaluation…

Schedule your expert service or consultation with our refrigeration specialists today.

Our expert team is committed to delivering reliable and efficient solutions that ensure optimal system performance in every industrial plant.

Feel free to reach out to us anytime for any concerns regarding ammonia training or the industrial refrigeration system. Good luck!